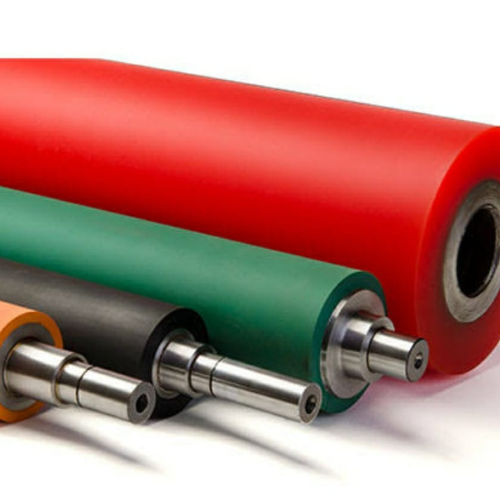

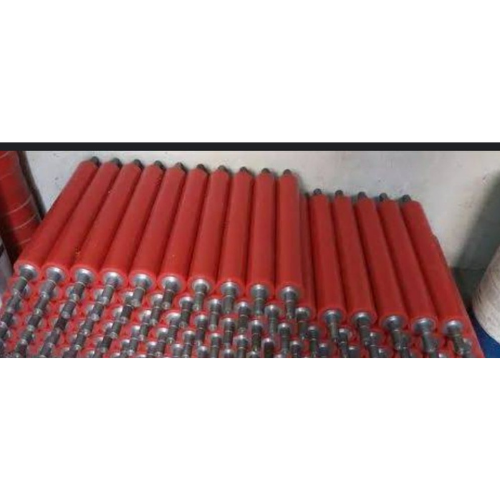

PO Roller

A PU roller, also known as a polyurethane roller, is a type of roller made from polyurethane material. It is commonly used in various industries and applications due to its excellent performance and durability.

Here are some key characteristics and features of PU rollers:

1. Material: PU rollers are manufactured using polyurethane, a synthetic material known for its high abrasion resistance, toughness, and load-bearing capacity. Polyurethane is a versatile material that can be formulated to meet specific requirements, including hardness, chemical resistance, and temperature resistance.

2. Applications: PU rollers find applications in diverse industries, including manufacturing, printing, packaging, material handling, textiles, food processing, and more. They are commonly used for conveying, guiding, gripping, or applying pressure in various machinery and equipment.

3. Durability: PU rollers are highly durable and resistant to wear and tear. They can withstand heavy loads, repetitive impact, and friction, making them suitable for demanding industrial environments.

4. Excellent friction properties: PU rollers offer excellent friction properties, which help in achieving smooth and efficient operation. They provide good traction and grip, minimizing slippage and ensuring precise movement.

5. Noise and vibration reduction: PU rollers have inherent noise and vibration damping properties. They help reduce noise levels and minimize vibrations during operation, contributing to a quieter and more stable machinery performance.

6. Resistance to chemicals and oils: Polyurethane material used in PU rollers has good resistance to chemicals, oils, solvents, and other corrosive substances. This resistance allows PU rollers to maintain their performance and integrity even in challenging environments.

7. Wide range of hardness options: PU rollers are available in various hardness levels, ranging from soft to hard. The hardness is measured on the Shore durometer scale, with higher values indicating greater hardness. The selection of the appropriate hardness depends on the specific application requirements.

8. Easy customization: PU rollers can be customized to meet specific application needs. They can be molded into various shapes, sizes, and configurations, allowing for precise fitment and integration into different machinery and equipment.

Overall, PU rollers are preferred in industrial applications due to their durability, excellent friction properties, resistance to chemicals, and customization options. They contribute to improved efficiency, reduced maintenance, and extended service life of machinery and equipment.

Reviews

There are no reviews yet.